Activity Area #1:

Analysis of technology in the market

and in the pipeline

Lead: PROPHESY

Objectives:

1. Identification of a reference model for compiling existing technology that:

-

provides the means for diverse data collection, consolidation and interoperability

-

supports digital automation functions that will close the loop to the field and will enable “autonomous” maintenance functionalities

-

allows the use of novel concepts (e.g. AR) in maintenance scenarios with particular emphasis on remote maintenance

-

complies with Industry 4.0 standardization

2. Analysis of existing approaches, including:

-

competitor analysis

-

technology maturity analysis

Main activities:

1. ForeSee Cluster reference architectural model

-

Mapping ForeSee Cluster projects’ architecture and components to the reference architecture, e.g. RAMI 4.0

-

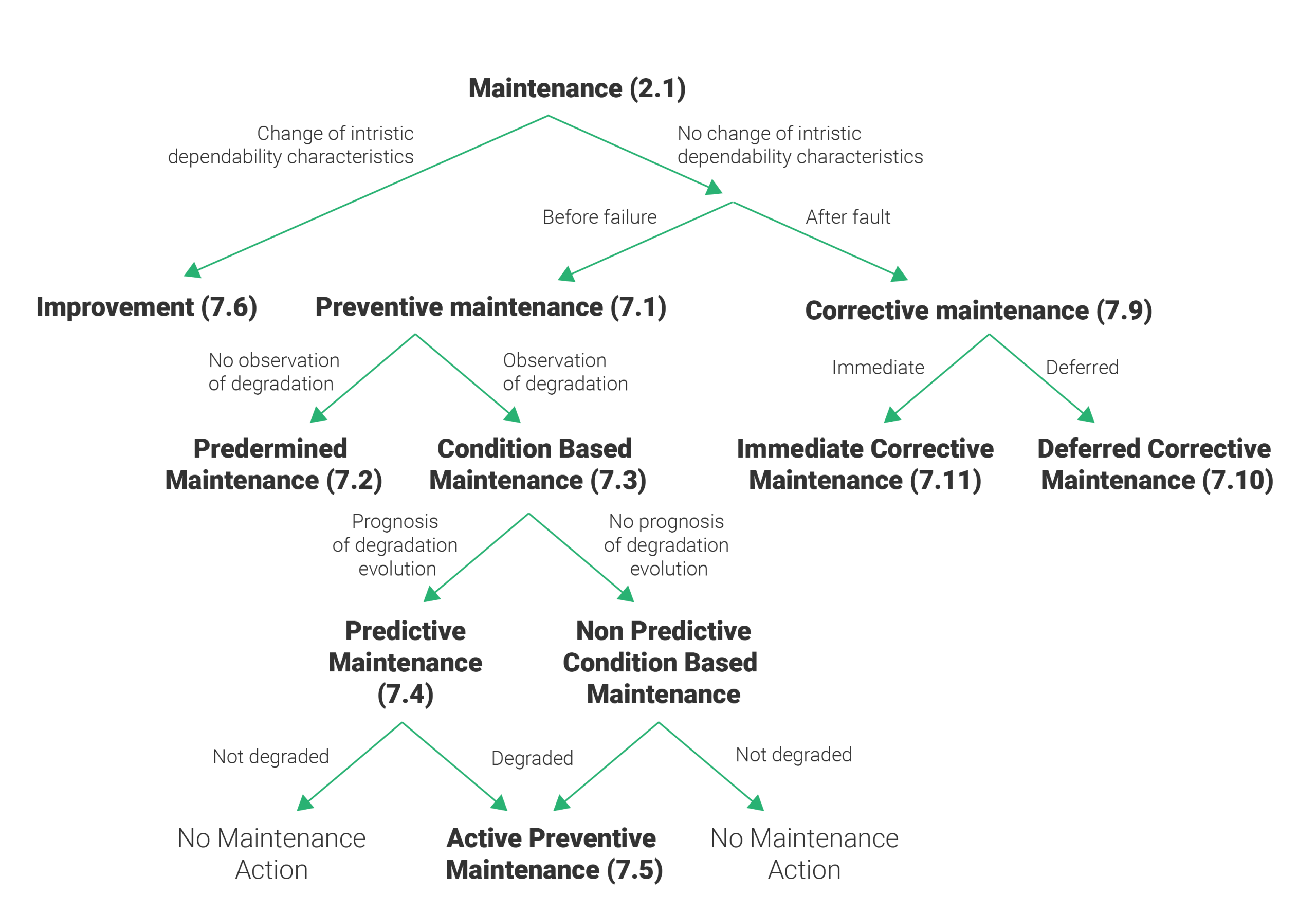

Alignment to Predictive Maintenance related Standards, e.g. EN 13306, EN 17007

2. Database providing Predictive Maintenance state-of-the-art approaches,

technologies and platforms

Activity Area #2:

ForeSee Predictive Maintenance

concept for the Factory of the Future

Lead: PROGRAMS

Objectives and main activities:

1. Identification of the scientific and technological

common ground that links the Foresee Cluster projects:

Scientific:

-

Reliability-based maintenance approaches

-

Trustworthy predictive maintenance

-

Trend reference models for prediction of equipment condition

-

Integrated quality-maintenance methods and tools

-

Synchronise maintenance with production planning and logistics

-

Failure modes, effects, and criticality analysis (FMECA) techniques

-

Physically-based models

-

Optimization of availability, maintainability, quality, safety while considering the system as a whole and throughout the production lifecycle.

-

Transferability to different industrial sectors (versatility)

Technological:

-

Integration of very different actors (common platform vs networks of Smart Objects Technologies)

-

Standard communication protocols and data formats

-

Vertical and horizontal scalability

-

Security at all levels

-

Data safety

-

Big data management

-

Low level data collection, filtering and cleaning

-

Exploitability from low CPU power end points (mobiles)

2. Creation of a common reference model that allows

depicting all ForeSee Cluster projects workflows

-

Select and agree on a general model to cover all projects architectures (e.g. RAMI 4.0)

-

Adapt the general model to specific project needs to allow further indentification if integration of cluster solutions is possible

Activity Area #3:

Trend-setting

for the future factory

Lead: Z-BRE4K

Objectives and main activities:

1. Interoperability of future factory approaches for PdM

-

Retrofitting of physical models design

-

RUL estimation

-

FMECA

-

Digital twins

-

Data spaces

-

Cognitive manufacturing

-

Industrie 4.0 and RAMI compliance

2. Applications of key indicators for PdM

-

Maintenance Terminology – EN 13306:2017

3. Identifications of available maintenance standards

-

Describe the maintenance landscape

-

Identify the knowledge required at different levels of:

-

Technical director / Physical asset manager

-

Maintenance manager

-

Maintenance engineer and supervisor

-

Maintenance technicians

Activity Area #4:

New model for sustainable factories

through efficient predictive maintenance

Lead: PRECOM

Objectives and main activities:

-

ForeSee business model: Predictive Maintenance offered as a service

-

Regulatory aspects

-

Data ownership and management

Activity Area #5:

Skills building paradigm

for predictive maintenance

Lead: SERENA

Objectives and main activities:

1. Education and training methods on the new PdM methods and platforms

-

Training on maintenance strategies and reliability metrics

-

Virtual predictive analytics and AI techniques

-

Live data stream and application of data analytics

-

Simulated maintenance operation planning and operations

-

Provision of training materials and test releases

2. Roadmap and future trend for the industry

-

Condition monitoring and assessment at the edge

-

Data transfer to the cloud

-

Predictive analytics and fault diagnosis/prognosis

-

Maintenance operations management

-

Standardisation

Activity Area #6:

Community building

and dissemination

Lead: UPTIME

Objectives:

-

To build a sustainable European industrial and academic community for predictive maintenance

-

To create opportunities for joint exploitation

-

To foster transfer of expertise and best practices

Main activities:

1. Dissemination

-

Improve academic results by collaboration on common topics

-

Improve dissemination impact and awareness based on joint initiatives

-

Exchange best practices

2. Community Building & Management

-

Establish infrastructure for cluster community management

-

Widen outreach by combining existing project communities

-

Foster a broad ecosystem of potential customers

3. Synergies with other Initiatives

-

Exchange best practices on cross-cutting topics

-

Increase awareness of predictive maintenance in other communities

-

Capture new channels for exploitation of cluster results

ForeSee is a cluster of six projects, which have received funding from the European Union’s Horizon 2020 research and innovation programme under the FoF9 call.